That shipping error last Tuesday? It cost you at least $38.50.

Probably more.

That’s just the hard cost of the return, reshipment, and labor.

The real cost? The customer you just lost. Because 69% of shoppers are unlikely to buy from you again if an order is more than two days late.

Here’s the thing: It’s not your pickers. It’s your process.

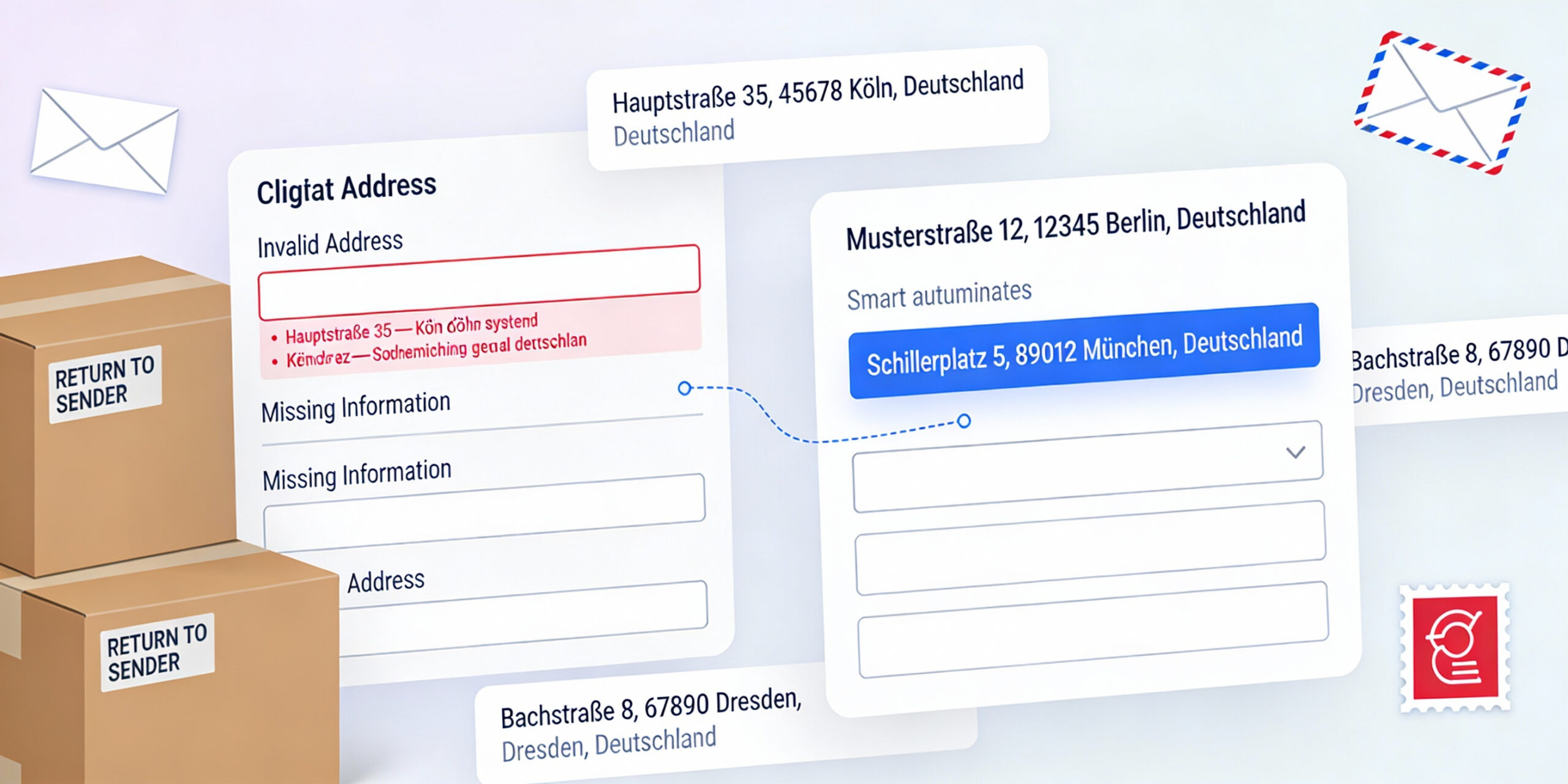

You’re solving the problem at the wrong end of the assembly line. The mistake happens the second an order with a bad address hits your system, not when a label gets slapped on the box.

Every minute your team spends manually fixing addresses or flagging weird order notes is cash lit on fire.

These are decisions that should be automated before a picker ever sees the order.

So what’s the fix?

You need a pre-fulfillment checkpoint. An automated gatekeeper that stops problem shipments before they start.

Think of it as a bouncer for every order. It checks the ID, makes sure the details are legit, and decides if the order gets in or gets held.

This isn’t a massive IT project. It’s a set of simple “if-then” commands you control.

Ready to set some rules? Here’s how you get started in the next 10 minutes.

Flag bad addresses.

Do this: Create a rule to automatically hold any order with “PO Box,” an incomplete zip code, or an APO/FPO address. The system flags it for a human to review.

Why it works: This is your first line of defense against returns and carrier surcharges. You stop wasting money on bad data.

Pick the right carrier.

Do this: Set a rule that says, “If the address contains ‘PO Box,’ automatically assign USPS as the carrier.”

Why it works: Your system won’t default to FedEx or UPS and hit you with a massive surcharge. This simple rule stops preventable mistakes. No more surprise fees.

Catch compliance issues.

Do this: Create a rule to flag any order with a restricted item (like alcohol or batteries) going to a state or country with known restrictions.

Why it works: This prevents costly customs rejections and fines. With 73% of merchants reporting problems with international shipments, this guardrail saves you from a world of headaches.

The move?

You implement these simple rules, and your entire warehouse changes.

Decisions that took hours of manual review are now made in seconds.

Brands that do this see picking errors drop by 20%, because the quality of info reaching the floor is better.

You stop burning cash on returns.

Your team stops wasting time on manual fixes.

And customers get their orders on time. That’s the only thing they really care about.

That’s it. Go fix your shipping.